Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

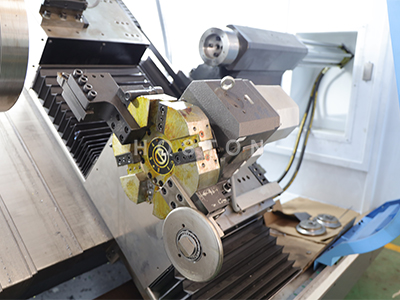

When the CNC Lathe is used, the automatic rotary tool holder often fails, and many people do not know how to solve it.

Fault 1: The tool holder of the Cnc Lathe is shifted, but the tool holder has turned to multiple tool positions and cannot be fixed on any tool position.

Cause Analysis: The Hall element for detecting the position of the tool post is faulty. The CPU board or position signal board of the control system is faulty.

Elimination measures: Detect the static and dynamic parameters of the Hall element, such as abnormal parameters, replace parts. Replace the CPU board and locate the multiplier board.

Fault 2: The CNC Lathe tool holder is indexed, but the lock is not tight or in place, and the tool holder will shake left and right when pulled by hand.

Cause analysis: The reverse circuit of the tool holder motor is faulty, and the motor does not reverse, because when the tool rotates, the motor should reverse immediately, put down the tool holder body, and position and lock it in the positioning groove of the tool holder base. If the motor does not reverse, the above actions cannot be completed, and the knife holder will become loose. When the tool holder is rotated, the initial position of the screw used to raise and lower the tool holder is wrong, so the recovery position is also wrong.

Troubleshooting measures: Check the reverse control circuit of the motor, disassemble the tool holder body, and adjust the initial position of the notch of the boss of the bolt rod and the target.

Fault 3: The CNC Lathe tool post does not rotate (generally the system will prompt that the position signal is wrong), there are various reasons that can cause the tool post to not rotate.

Cause Analysis:

1. The tool holder relay is disconnected after overload. Tool post motor 380V phase error. Since the tool post can only rotate clockwise (there is a directional positioning mechanism inside the tool post), if the three-phase connection is wrong, the tool post motor will reverse immediately after being powered on, and the tool post cannot rotate.

2. The three-phase phase of the knife post motor is missing. The 24V power supply used for the position signal of the tool holder fails, and the thrust ball bearing 7 on the central shaft 2 of the tool holder body is crushed by the axial positioning disc. The bearing cannot rotate, so that the knife rest motor cannot drive the knife rest to rotate.

3. The "system position board" of the control system is faulty. After the tool holder is in place, the "system positioning board" should be able to detect the position signal of the tool holder.

Remedy: Check the strong current circuit of the machine tool, remove the tool holder, adjust the thrust ball bearing to the clearance, replace the damaged parts, check the 24V power supply, and replace the "system positioning board".

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.