Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

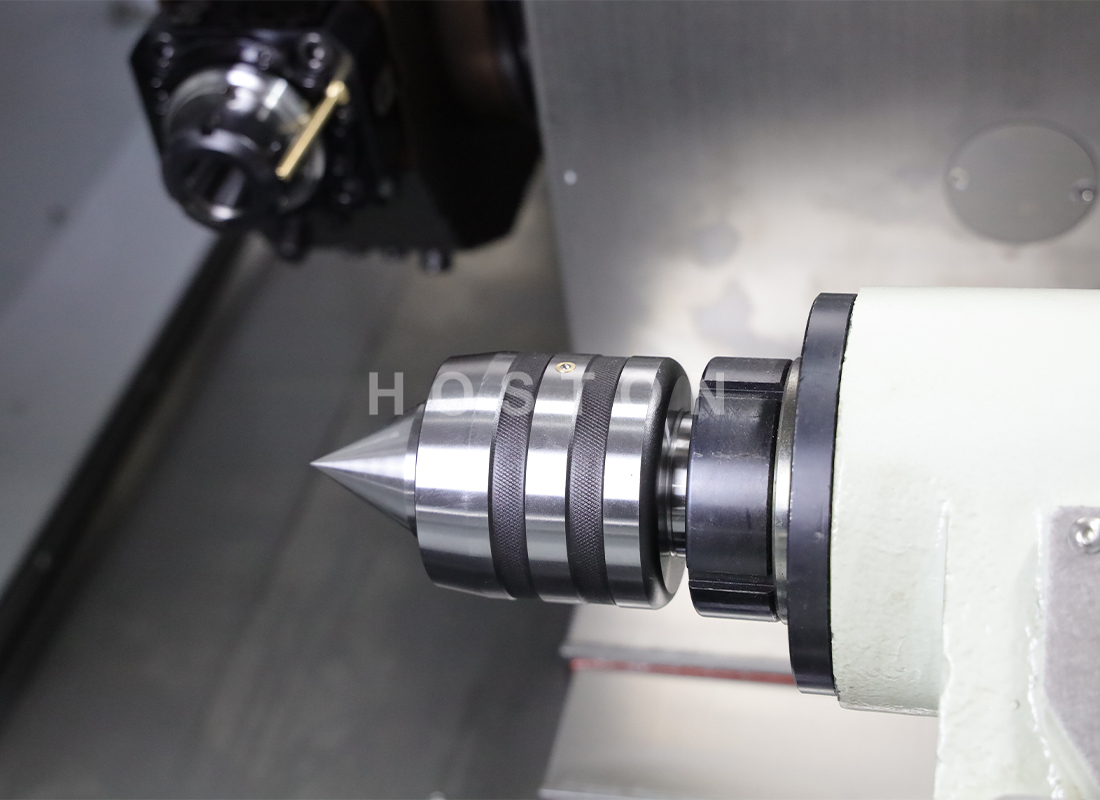

The structure of CNC Lathe generally includes two types: organic clip-on type and integral welding type.

Commonly used turning tool head materials include carbide, high-speed steel, ceramics, etc. Each material has its own scope of application and shortcomings.

Carbide turning tool bits are currently one of the most widely used turning tool bits. They are mainly used for precision cutting of metal materials, and are especially suitable for processing high-hardness and high-strength materials.

High-speed steel turning tool heads are made of high-hardness high-speed steel. They have high hardness and thermal stability and are suitable for processing low-hardness metal materials.

Ceramic turning tool bit is a new type of turning tool bit made of high-quality alumina, silicon carbide and other materials. The cutter head has high cutting efficiency, good cutting quality, long life, and shows excellent stability under working conditions such as high speed, high temperature and high pressure. However, there are also obvious disadvantages, such as being expensive and not suitable for processing brittle materials.

The types of turning tool heads are divided into regular triangles, quadrilaterals, pentagons, hexagons, etc.

Types of indexable turning tools for CNC Lathe

1. Lever type: It consists of lever, screw, knife pad, knife pad pin and blade. This method relies on the screw to be tightened against the lever, and the force of the lever is used to compress the blade to achieve the purpose of clamping. Its characteristics are suitable for all kinds of inserts with positive and negative rake angles. The effective rake angle range is -60~+180; chips can flow through without hindrance, and cutting heat does not affect the screw holes and levers; both groove walls provide strong support for the inserts. , and ensure the indexing accuracy.

2. Wedge type: composed of set screw, tool pad, pin, wedge and blade. This method relies on the extrusion force between the pin and the wedge to tighten the blade. Its characteristics are suitable for various negative rake angle inserts, and the effective rake angle range is -60~+180. There are no grooved walls on both sides, leaving a gap for easy copy cutting or reversing operations.

3. Wedge clamping type: It consists of set screws, tool pads, pins, compression wedges, and blades. This method relies on the pressing force of the pin and wedge to clamp the blade. Its characteristics are the same as the wedge type, but the chips are not as smooth as the wedge type. In addition, there are bolt press-on type, pressure hole type, press-on type and other forms.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.